Penetrant Testing

Penetrant testing (PT) is an easy-to-use non-destructive testing method. Penetrants with low surface tension and high capillary effect are used. This allows them to easily penetrate openings in the test part surface such as surface pores or fine cracks with gap widths in the µm range (≥ 25 µm).

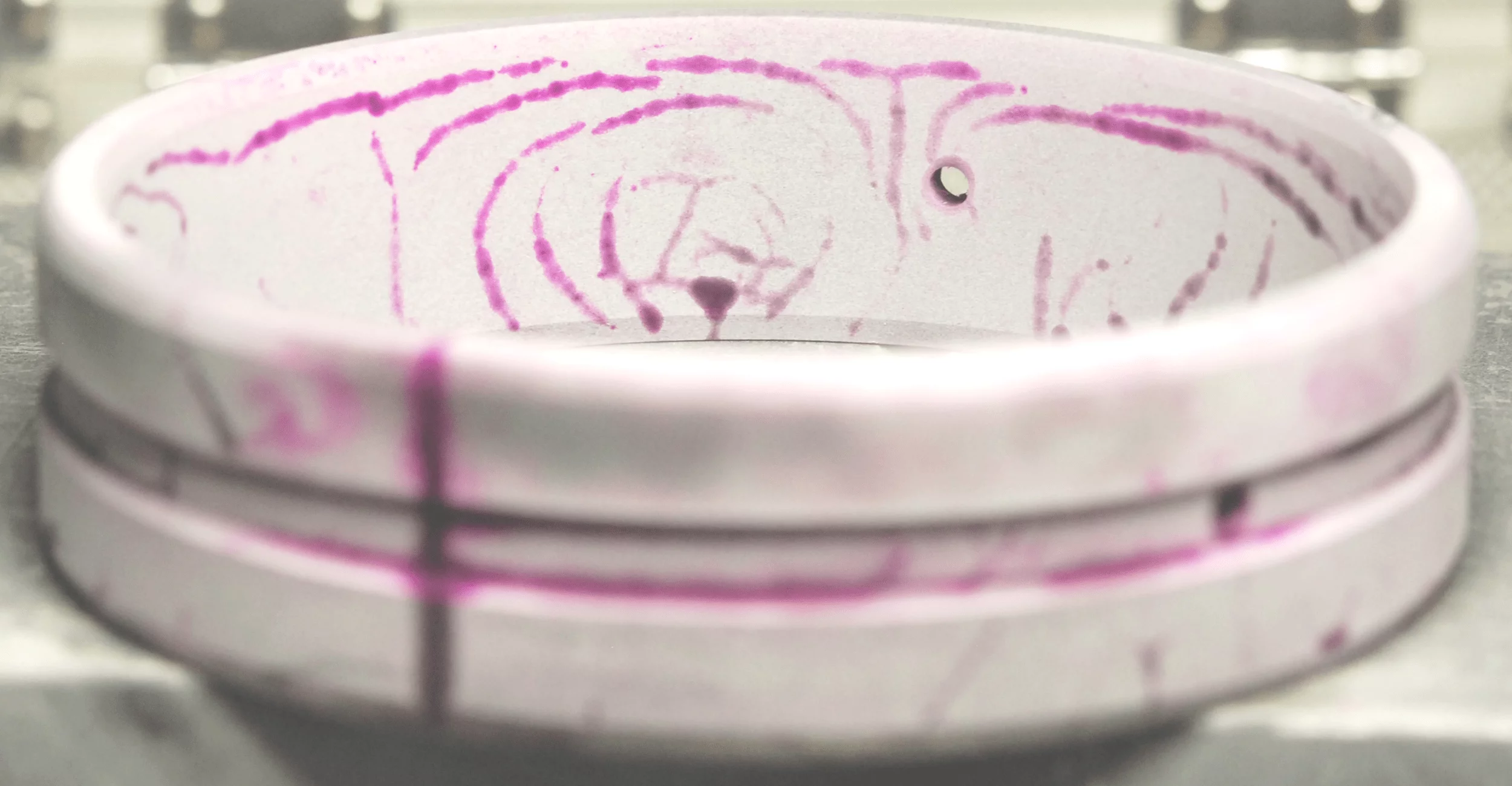

Colour contrast penetrant testing of a bearing ring

Fluorescent penetrant testing of a bearing ring

Typical indications that can be detected with the penetrant testing are:

- Cold cracks

- Hot cracks

- Grinding cracks

- Gas pores and clustered porosities

- Spongy texture

- Stress corrosion cracking

Depending on which penetrant is used, a distinction is made between three methods according to EN ISO 3452 Part 2:

- TYPE I Fluorescent Penetrant Testing

- TYPE II Colour Contrast Penetrant Testing

- TYPE III Fluorescent Colour Contrast Penetrant Testing

The basic standard for penetrant testing EN ISO 3452 Part 1 describes in detail how to perform penetrant testing with the various testing products systems.

Process steps of the colour contrast penetrant testing

In the following, the essential steps in performing colour contrast penetrant testing using the red-white method are presented. A solvent-based wet developer (form e) is used.

(1) Precleaning

Mechanical pre-cleaning -

Brushing, sanding, blasting

Precleaning ensures that the surface of the test object is free of contaminants. Impurities can be e.g.: rust, grease or scale. Any indications that may be present are thus made accessible for penetration by the penetrant. Precleaning can be performed:

- mechanical - e.g. brushing, grinding, blasting

- chemical - by means of cleaning agents, whereby these must be removed from the surface after the cleaning process

(2) Application of the penetrant (penetration)

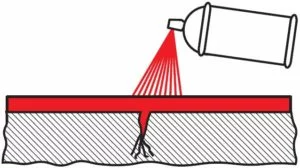

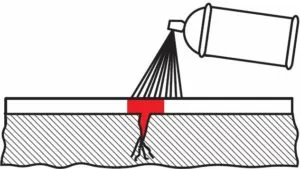

Penetrate -

uniform application of the colored (or fluorescent) penetrant

The penetrant is sprayed onto the dry surface to be tested. The penetrant can also be applied with a brush. Or the test object is poured over with or immersed into the penetrant. The penetration time can be 5 minutes - 60 minutes. This depends on the test conditions (e.g. temperature) and the test object material .

(3) Excess penetrant removal

Removal of excess penetrant, e.g. with a sponge

During excess penetrant removal, the excess penetrant is carefully removed from the test object surface after the specified penetration time. A lint-free cloth or sponge is used for this purpose. The test surface is carefully inspected for residues.

(4) Drying

Drying the test object surface with moving air

Before the developer can be applied, the test object surface must be dry (except when using a water-based developer, form b and c). This is achieved by:

- Wiping with a dry lint-free cloth

- Evaporation

- Forced ventilation (e.g. hair dryer, compressed air)

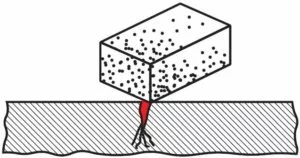

(5) Application of the developer

Uniform spraying of the white developer

The developer is applied evenly to the test object surface. A thin, homogeneous, white layer is formed. This ensures that the penetrant remaining in the surface openings is bleeding out.

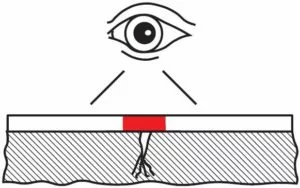

(6) Inspection

Inspection of the test object surface, indications "bleed" out

Immediately after application of the developer, the test object surface is inspected according to the given inspection intervals. The required viewing conditions (see EN ISO 3059, ASTM E1417 or customer specification) are observed.

The test result and the test conditions are recorded by the NDT personnel in the test report. Depending on the test instruction or specification, documentation by fotos or video recordings are made.

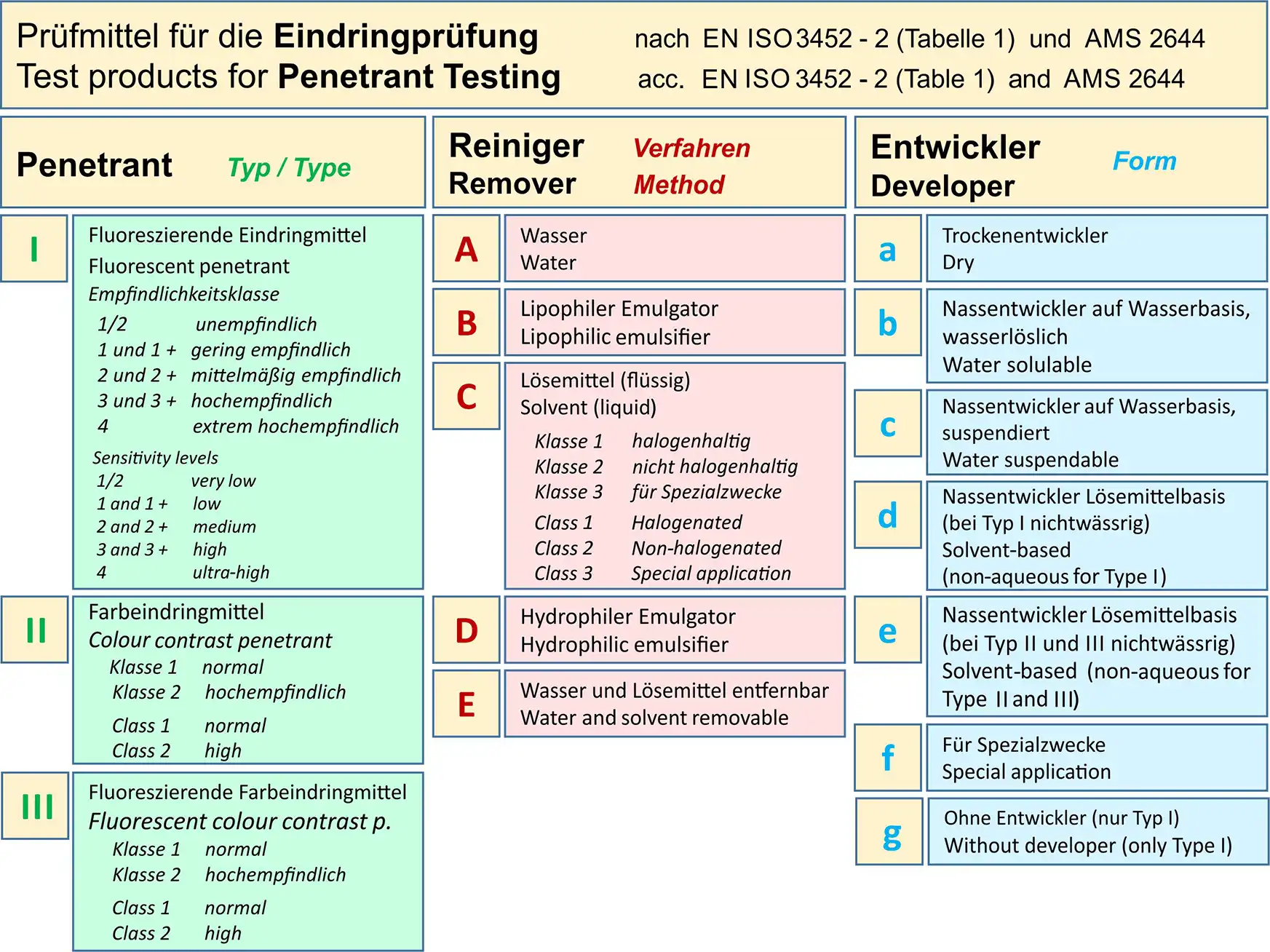

Classification of penetration systems according to EN ISO 3452 Part 2

Testing products for penetrant testing are classified by

- Type of penetrant

- Method of excess penetrant removal

- Form of development

(see EN ISO 3452-2 Table 1 above)

Fluorescent penetration systems are classified according to sensitivity levels starting with ½ (very low) to 4 (ultra-high sensitivity).

There are two sensitivity classes for color contrast penetration systems and fluorescent colour contrast penetration systems:

| Sensitivity class 1 | normal |

| Sensitivity class 2 | highly sensitive |

NORD-TEST

Showing 1 - 7 out of 7

Page 1 out of 1

|

NORD-TEST Reiniger U 87

|

|

|

121.300.101

|

|

|

NORD-TEST Kontrastrot U 88

NORD-TEST Kontrastrot U 88 is a red penetrant for colour contrast penetrant testing

TYPE II class 2

|

|

|

121.300.201

|

|

|

NORD-TEST Entwickler U 89

NORD-TEST Entwickler U 89 is a white developer

FORM

|

|

|

121.300.701

|

|

|

NORD-TEST ROT 3000

NORD-TEST Rot 3000 is a red fluorescent penetrant

TYPE III class 2

|

|

|

121.300.301

|

|

|

NORD-TEST Set

1 set consists of: |

|

|

121.300.750

|

|

|

NORD-TEST Penetrant FP 90 Blau N

NORD-TEST Penetrant FP 90 Blau N is a blue fluorescent penetrant

TYPE I class 2

|

|

|

122.500.125

|

|

|

NORD-TEST Food Penetrant

Food-safe colour contrast penetrant

TYPE III - corresponds to class 2

|

|

|

124.000.102

|

Standard-Chek

Showing 1 - 4 out of 4

Page 1 out of 1

|

Standard-Chek Reiniger Nr. 1

Remover for the penetrant testing system Standard-Chek

|

|

|

121.200.101

|

|

|

Standard-Chek Kontrastrot Nr. 2

Standard-Chek Kontrastrot Nr. 2 is a red penetrant of high contrast for colour contrast penetrant testing

Type II class 2

|

|

|

121.200.201

|

|

|

Standard-Chek Entwickler Nr. 3

Standard-Chek Entwickler Nr. 3 is a white developer for penetrant testing

|

|

|

121.200.501

|

|

|

Standard-Chek Rot 2003

Red fluorescent penetrant for fluorescent colour contrast penetrant testing Type III class 2

|

|

|

121.200.301

|

MET-L-CHEK Penetrant

Showing 1 - 17 out of 17

Page 1 out of 1

|

MET-L-CHEK Penetrant Dye VP-30

*** Qualified according to AMS 2644E and QPL-2644 listed TYPE II class 2

METHOD of excess penetrant removal

|

|

|

121.100.201

|

|

|

MET-L-CHEK Rot 1001

* Corresponds to AMS 2644E Type III Class 2

METHOD of excess penetrant removal

|

|

|

121.100.301

|

|

|

MET-L-CHEK Penetrant VBP 300

*** Qualified according to AMS 2644E and QPL-2644 listed TYPE II class 2

METHOD of excess penetrant removal

|

|

|

121.100.222

|

|

|

MET-L-CHEK Penetrant VP 302

*** Qualified according to AMS 2644E and QPL-2644 listed TYPE II class 2

METHOD of excess penetrant removal

|

|

|

123.200.203

|

|

|

MET-L-CHEK Penetrant FP-90

MET-L-CHEK Penetrant FP-90 is a water-washable fluorescent penetrant. TYPE I Level 1/2

METHOD of excess penetrant removal

|

|

|

122.101.102

|

|

|

MET-L-CHEK Penetrant FP 91

MET-L-CHEK Penetrant FP 91 is a water washable fluorescent penetrant. TYPE I Level 1/2

METHOD of excess penetrant removal

|

|

|

122.101.162

|

|

|

MET-L-CHEK Penetrant FP 91 B

MET-L-CHEK Penetrant FP 91 B is a water-washable fluorescent penetrant TYPE I Level 1/2

METHOD of excess penetrant removal

|

|

|

122.101.502

|

|

|

MET-L-CHEK Penetrant FBP 911

*** Qualified according to AMS 2644E and QPL-2644 listed |

|

|

122.101.602

|

|

|

MET-L-CHEK Penetrant FP 921

*** Qualified according to AMS 2644E and QPL-2644 listed Water-washable fluorescent penetrant TYPE I Level 1

METHOD of excess penetrant removal

|

|

|

122.101.612

|

|

|

MET-L-CHEK Penetrant FBP 912

*** Qualified according to AMS 2644E and QPL-2644 listed MET-L-CHEK Penetrant FBP 912 is a water-washable fluorescent penetrant TYPE I Level 2+

METHOD of excess penetrant removal

|

|

|

122.101.902

|

|

|

MET-L-CHEK Penetrant FP 922

*** Qualified according to AMS 2644E and QPL-2644 listed Water-washable fluorescent penetrant TYPE I Level 2+

METHOD of excess penetrant removal

|

|

|

122.102.602

|

|

|

MET-L-CHEK Penetrant FBP 913

*** Qualified according to AMS 2644E and QPL-2644 listed MET-L-CHEK Penetrant FBP 913 is a water-washable fluorescent penetrant TYPE I Level 3+

METHOD of excess penetrant removal

|

|

|

122.101.142

|

|

|

MET-L-CHEK Penetrant FP-923

*** Qualified according to AMS 2644E and QPL-2644 listed

Water-washable fluorescent penetrant

TYPE I Level 3+

|

|

|

122.102.621

|

|

|

MET-L-CHEK Penetrant FBP 914

*** Qualified according to AMS 2644E and QPL-2644 listed MET-L-CHEK Penetrant FBP 914 is a water-washable fluorescent penetrant TYPE I Level 4

METHOD of excess penetrant removal

|

|

|

122.101.152

|

|

|

MET-L-CHEK Penetrant FP 93 A (M)

*** Qualified according to AMS 2644E and QPL-2644 listed Post-emulsifiable fluorescent penetrant TYPE I Level 2

|

|

|

122.102.302

|

|

|

MET-L-CHEK Penetrant FP 95 A (M)

*** Qualified according to AMS 2644E and QPL-2644 listed Post-emulsifiable fluorescent penetrant TYPE I Level 3

|

|

|

122.101.401

|

|

|

MET-L-CHEK Penetrant FP 97 A (M)

*** Qualified according to AMS 2644E and QPL-2644 listed Post-emulsifiable fluorescent penetrant TYPE I Level 4

|

|

|

122.102.502

|

MET-L-CHEK Developer

Showing 1 - 5 out of 5

Page 1 out of 1

|

MET-L-CHEK Developer D70

*** Qualified according to AMS 2644E and QPL-2644 listed

FORM

|

|

|

121.100.501

|

|||||||||

|

MET-L-CHEK Developer D702

MET-L-CHEK Developer D702 is a developer for high temperatures from +52 °C to +177 °C FORM

|

|

|

123.200.403

|

|||||||||

|

MET-L-CHEK Developer D 78 B

*** Qualified according to AMS 2644E and QPL-2644 listed

FORM

|

|

|

122.120.406

|

|||||||||

|

MET-L-CHEK Developer D 72 A

*** Qualified according to AMS 2644E and QPL-2644 listed MET-L-CHEK Developer D 72 A is a dry developer for fluorescent penetrant testing. Suitable for

FORM

|

|

|

122.120.306

|

|||||||||

|

MET-L-CHEK Developer D 76 B

*** Qualified according to AMS 2644E and QPL-2644 listed MET-L-CHEK Developer D 76 B is a water-soluble developer for post-emulsifiable fluorescent penetrants.

FORM

|

|

|

121.100.606

|

MET-L-CHEK Remover

Showing 1 - 5 out of 5

Page 1 out of 1

|

MET-L-CHEK Spezialreiniger NPU

* Meets the requirements of AMS 2644E

|

|

|

121.100.101

|

|

|

MET-L-CHEK Remover E 59 A

*** Qualified according to AMS 2644E and QPL-2644 listed

|

|

|

122.113.101

|

|

|

MET-L-CHEK Reiniger R 502

Special remover MET-L-CHEK Reiniger R 502

|

|

|

123.200.103

|

|

|

MET-L-CHEK Remover R-503

*** Qualified according to AMS 2644E and QPL-2644 listed

|

|

|

122.113.112

|

|

|

MET-L-CHEK R-504 Spray

MET-L-CHEK Cleaner & Remover R-504 Spray *** Qualified according to AMS 2644E and QPL-2644 listed

|

|

|

112.113.121

|

MET-L-CHEK Emulsifier

Showing 1 - 1 out of 1

Page 1 out of 1

|

MET-L-CHEK Emulgator E 58 D

*** Qualified according to AMS 2644E and QPL-2644 listed MET-L-CHEK Emulsifier E 58 D is a hydrophilic emulsifier concentrate

Dilution

METHOD

|

|

|

122.112.202

|

Reference blocks and test bodies

Showing 1 - 10 out of 10

Page 1 out of 1

|

Reference test block 1

according to EN ISO 3452-3* Scope of delivery

|

|

|

127.400.001

|

|

|

Reference test block 2

according to EN ISO 3452-3* Scope of delivery

|

|

|

127.550.000

|

|

|

Reference test block NR-5 (PSM-5)

HELLING reference test block |

|

|

127.800.010

|

|

|

Reference test block according to ASME V

Aluminum test block acc. to

|

|

|

127.100.000

|

|

|

Reference test block according to JIS Z 2343

Determination of the sensitivity levels of penetrant systems |

|

|

127.700.000

|

|

|

Washing test panel WTP-1

Evaluation of washability of fluorescent penetrants acc. to ASTM E1417/E1416M and AMS 2644H. |

|

|

127.700.001

|

|

|

Washing test panel WTP-2

Evaluation of the water washability of fluorescent penetrants. |

|

|

127.700.002

|

|

|

Test body UTE-3

Test scale and

|

|

|

127.850.000

|

|

|

Comparator black

Precise sizing |

|

|

128.200.001

|

|

|

Comparator green fluorescent

Precise determination of the size of indication of fluorescent magnetic particle testing |

|

|

128.200.102

|

PT test kit

Showing 1 - 1 out of 1

Page 1 out of 1

|

Test kit for Penetrant Testing Test kit for colour contrast penetrant testing

CONTENT 1 x NORD-TEST Kontrastrot U 88 Spray (red penetrant, 1 x 500 mL) 2 x NORD-TEST U87 remover (500 mL each) 3 x NORD-TEST U89 developer (500 mL each) 1 x MET-L-CHEK FP 93 A(M) penetrant (250 ml) 2 x MET-L-CHEK NPU remover (400 mL each) 3 x MET-L-CHEK D70 developer (400 mL each) 1 reference block according to ASME 1 UV LED lamp, type UV Inspector 2020 1 white light LED pocket lamp 1 pair of protective gloves 1 wire brush 1 box cleaning wipes |

|

|

121.500.100

|

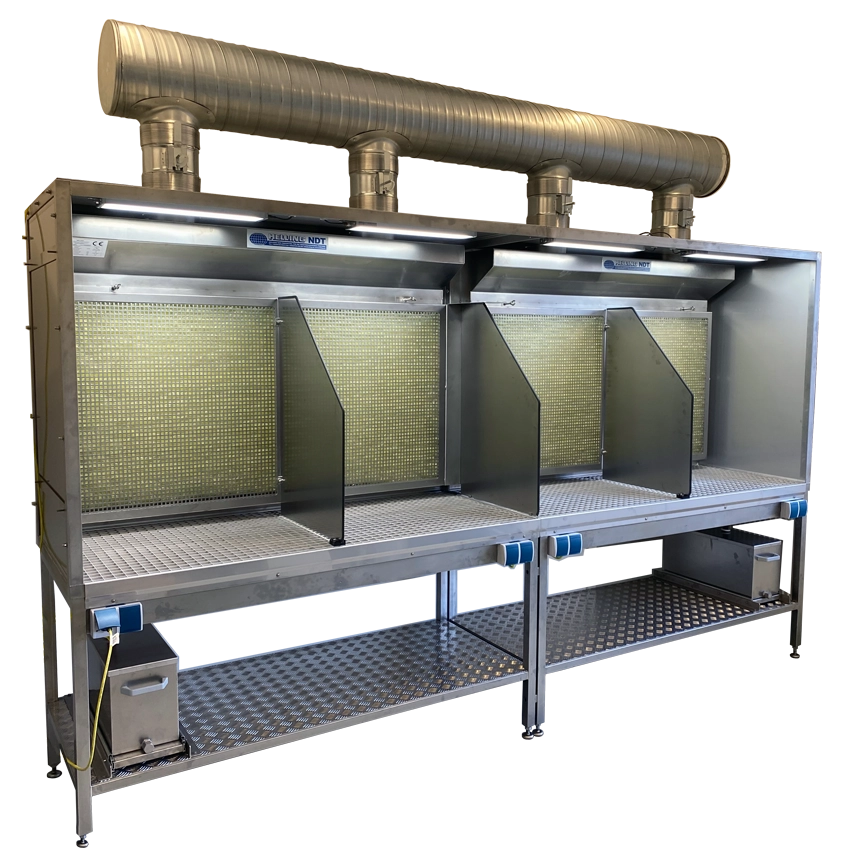

PT test facilities

HELLING test facilities for penetrant testing are individually manufactured according to the customer's specification. The facilities are mainly made of stainless steel. The control systems are produced by well-known manufacturers.

A test facility is composed of the following process stations:

- Pre-cleaning

- Washing

- Draying → temperature up to 100 °C

- Cooling → temperature up to 40 °C

- Application of the penetrant

- Washing

- Emulsifying

- Re-washing

- Drying → temperature 60 °C

- Application of the developer

- Inspection

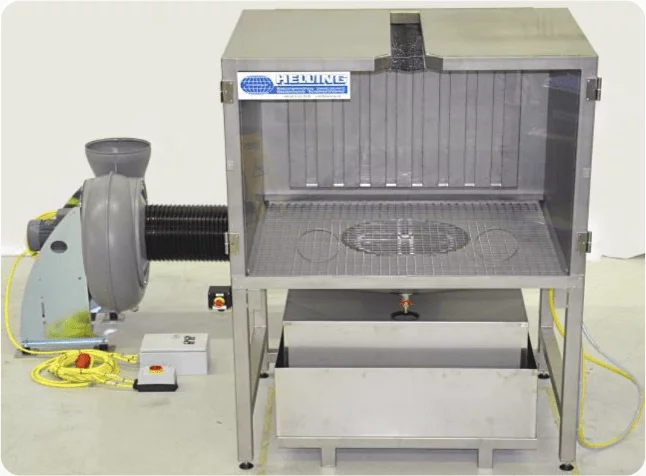

PT test station in tabletop version (standard equipment)

Stationary penetration table with collecting basins and manually operated turntable

The equipment meets the requirements of the following regulations:

- DIN EN ISO 3452-1

- SAE AMS 2644

- MIL-STD-6866

- MIL-I-25135E (replaced by SAE AMS 2644)

European technical regulations regarding occupational health, operational safety and ergonomics are complied with.If you would like to discuss your specification with us, please send us your request via the watch list or by e-mail to!We would also be happy to guide you through our NDT exhibition in Hamburg and advise you on your testing problem! Mehr Informationen ...

+49 4122 922 - 0

+49 4122 922 - 0  info@helling.de

info@helling.de  Mo. - Do. : 8:00 - 16:30 Fr. : 8:00 - 13:00

Mo. - Do. : 8:00 - 16:30 Fr. : 8:00 - 13:00